Welcome to

Heze Sunflower lmport and Export Co., LTD

Your Trusted Partner for Custom Wooden Crafts & Paulownia Wood Solutions Since 2003.

Environmental

Derived from natural materials, it is a good choice for renewable resources.

Durable

Wood material is scratch-resistant, wear-resistant, warm, stable and safe

Beautiful

High-quality wood for a warm, comfortable or stylish visual effect

Talent Advantage

Talent is like the foundation of wood, stabilizing the growth of an enterprise.

Superb skill

Inheritors of traditional woodworking skills and technicians with modern equipment can produce high-quality, high-precision wood products.

Novel design

Design talents keep up with trends and innovative features to inject fashion elements into products and enhance their competitiveness.

Marketing accuracy

Understand the market and consumers, accurately position and expand multiple sales channels, and increase product exposure and sales.

Management Science

Effectively manage all aspects of the enterprise, allocate resources rationally, control costs, and prioritize team building and talent training.

The choice of materials

Professionals strictly control the quality of wood raw materials, ensure product quality from the source, and ensure product quality.

Strict quality inspection

Test products according to standards, handle quality issues, and continuously improve processes to ensure that products meet customer requirements.

About Heze Sunflower

Located in Cao County, Shandong Province—China’s largest base for Paulownia wood processing—Heze Sunflower Import and Export Co., Ltd. is a premier manufacturer and exporter of high-quality wooden crafts and furniture components.

Unlike trading companies, we own and operate a 50,000+ square meter factory equipped with advanced CNC woodworking machinery. For over 20 years, we have specialized in transforming raw timber into premium commercial products, serving B2B clients in Europe, North America, and Japan.

Our Manufacturing Capabilities

We provide end-to-end manufacturing solutions, from raw material sourcing to final packaging. Our facility is optimized for both high-volume wholesale orders and precise custom projects (OEM/ODM).

Raw Material Expertise: We have direct access to high-grade Paulownia, Poplar, Pine, and Oak wood. Being in the heart of the raw material source allows us to offer competitive factory-direct pricing.

Advanced Production Lines: Our workshop features precision sanding machines, cold press machines, laser cutting/engraving units, and automated spray painting lines.

Capacity:

Monthly Output: 50+ standard containers.

Warehouse Space: 20,000 square meters for safe storage and logistics management.

Why choose us?

Ingenuity is passed down, starting with every piece of wood product.

Enterprise advantage

Strong capacity

Advanced equipment and production lines enable the export of an average of 30 containers per month.

Rich products

Provide 20,000 kinds of wooden products, covering home, toys, office and other fields.

Advanced technology

Master a variety of processing techniques, such as laser engraving, screen printing, bronzing, etc.

Strong competitiveness

The annual export volume reaches 10 million US dollars, and the products are sold worldwide.

Product advantage

Exquisite craftsmanship quality assurance

Variety of categories

Excellent material

Process

Strong customization

Environmental health

High durability

Design diversity

Beautifully packaged

Talent advantage

Exquisite craftsmanship quality assurance

Professional team with rich experience

We have a professional technical team that has been engaged in the design and production of wood products for many years, and are familiar with wood processing techniques to ensure product quality and innovation.

Multidisciplinary cooperation, innovative research and development

The team members cover a wide range of fields, including design, engineering, and manufacturing, and are able to respond quickly to market demand and carry out creative design and technological upgrades of products.

International trade experience, accurate docking

The foreign trade team of the factory has rich experience in international trade, is familiar with the operation process and cultural nuance of overseas markets, and can provide customers with efficient and professional docking services.

Factory display

Ingenious woodworking, global quality.

Product Expertise

We specialize in three core categories tailored for global brands, retailers, and distributors:

1.Wooden Packaging & Storage: Custom wooden boxes for wine, jewelry, and gifts; storage crates and baskets.

2.Wooden Pet Products: Eco-friendly wooden pet urns, feeders, and houses.

3.Holiday & Home Decor: Laser-cut Christmas decorations, unfinished wood slices for crafts, and wall-mounted shelving.

4.Martial Arts Boards: Professional-grade Paulownia wood breaking boards for Taekwondo/Karate.

Why Choose Us? (Our Commitment to Quality)

In an era of uncertainty, we offer stability and transparency to our partners.

Certified Sustainability: We are committed to responsible forestry. Our factory holds FSC (Forest Stewardship Council) and ISO 9001 certifications, ensuring your products meet global environmental and quality standards.

Strict Quality Control (QC): Every batch undergoes moisture content testing (controlled below 12% to prevent cracking) and visual inspection before shipment.

Fast Turnaround:

Sample Lead Time: 5–7 days for custom designs.

Mass Production: 25–35 days depending on order complexity.

Visit Our Factory

We believe in transparency. Whether via a video call or an in-person visit, we welcome you to inspect our production lines in Cao County.

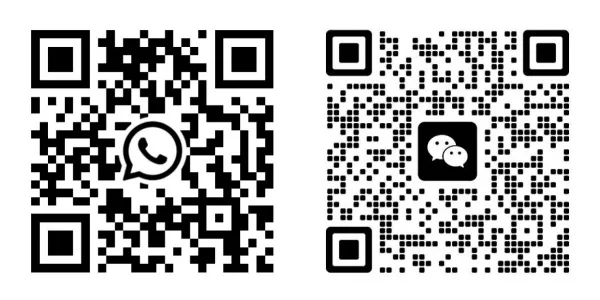

Contact us today to discuss your project or request a free quote. Let us bring your wooden product ideas to life with precision and care.